A dry-type transformer is a common electrical device used to transfer electrical energy from one circuit to another. In order to ensure normal operation and prolong the service life of the transformer, effective cooling methods are crucial.

There are two main cooling methods for dry-type transformers: natural cooling and forced cooling.

Free cooling refers to heat dissipation through natural convection and radiation. In free cooling, the transformer enclosure is usually designed with a good heat dissipation surface so that heat can be transferred out through the air. In addition, a cooling channel is provided inside the transformer to facilitate heat conduction and dissipation. The natural cooling method is simple and reliable, without additional energy consumption, and is suitable for some small and low-power dry-type transformers.

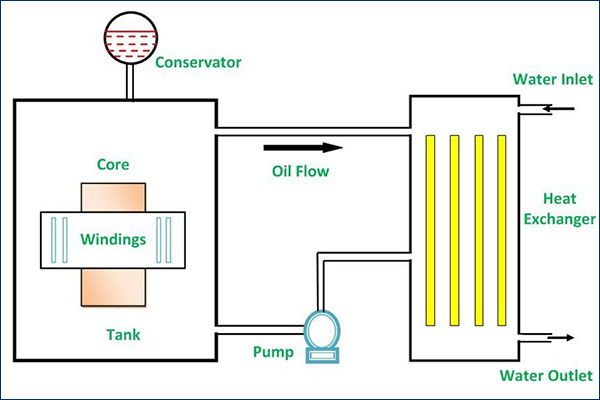

Forced cooling is to enhance the heat dissipation effect through fans or pumps. This cooling method is suitable for large and high-power dry-type transformers because of their higher heat dissipation requirements. In forced cooling, a fan or pump circulates air or a cooling medium to speed up the transfer and dissipation of heat. This method can effectively control the temperature of the transformer to ensure that it remains stable during high-load operation.

In addition to natural cooling and forced cooling, there are some other cooling methods for dry-type transformers, such as cooling plates and cooling tubes. These methods increase the cooling effect by increasing the cooling surface area, thereby keeping the temperature of the transformer within a reasonable range.

In summary, the cooling method of a dry-type transformer is critical to its proper operation and service life. Depending on the size and power of the transformer, an appropriate cooling method can be selected to ensure that the temperature of the transformer is always kept within a safe range.