The working principle of the diesel generator cooling system is one of the key factors to ensure the continuous operation of the generator. When the diesel generator is running, the internal components will generate a lot of heat. If the heat is not dissipated in time, it may cause the generator to overheat and damage.

How Does A Generator Cooling System Work?

The cooling system of the diesel generator is divided into an air cooling system and a water cooling system, which are described separately below.

1. Diesel generator air cooling system .

The air cooling system uses high-speed air flow to blow directly through the outer surface of the cylinder head and the cylinder body to dissipate the heat from the inside of the cylinder into the atmosphere to ensure that the generator works within the most favorable temperature range.

The cylinder and cylinder head of the diesel generator are cast with aluminum alloy with good heat transfer. In order to increase the heat area, each cylinder is generally manufactured separately. Many evenly arranged heat sinks are distributed on the surface of the cylinder and cylinder head to increase the heat dissipation area. The high-speed air flow when the engine is running is used to dissipate the heat into the atmosphere.

Since the diesel generator has a large power and needs to cool a lot of heat, axial flow fans with large power and flow are often used to enhance the cooling of the diesel engine.

In order to effectively utilize the air flow and ensure uniform cooling of each cylinder, the diesel generator is equipped with a deflector, a splitter plate and a cylinder liner deflector.

Although the air cooling system has the advantages of simple structure, light weight, few faults, and no special maintenance compared with the water cooling system, it is rarely used at present due to the high material quality requirements, uneven cooling, and high working noise. However, it is widely used in engineering machinery and agricultural equipment.

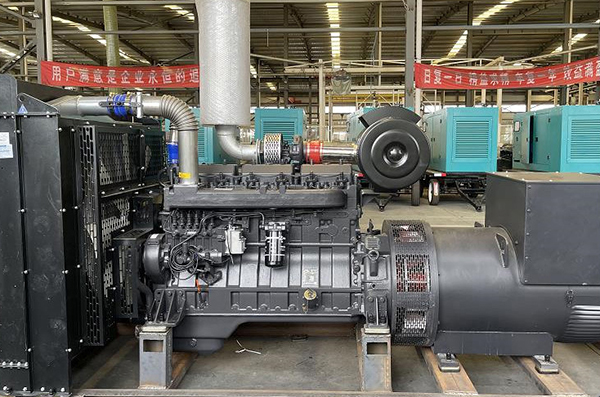

2.Diesel generator water cooling system

Composition of the water cooling system of the diesel generator: The main components that need to be cooled in the diesel generator include: the heat dissipation medium of the cylinder liner, cylinder head, lubricating oil, etc. is directly cooled by water, which is called a water-cooled diesel generator.

The water-cooled diesel engine requires a very complex cooling water circulation system, which includes components such as water pumps, radiators, fans and sensors, which work together to keep the operating temperature of the generator within a safe range.

When the generator is working, the water pump will draw the coolant from the water tank and send it to the various parts of the generator, so that the heat can be absorbed quickly;

Then, the coolant passes through the radiator, dissipates heat along the heat sink, and the hot air is discharged by the fan;

Finally, the coolant will return to the water tank for recycling to keep the cooling system working stably;