The diesel generator is a kind of internal combustion engine. Due to the high temperature generated by combustion, it is necessary to control the temperature of the engine through the cooling system to ensure the normal operation of the engine.

During the working process of the diesel generator set, the temperature of the mixed gas in the cylinder of the diesel engine after combustion is close to 1800°C, and the exhaust temperature is about 450°C.

If the entire system of the diesel engine is not cooled, the various parts of the diesel engine will reach a very high temperature, which will reduce the strength of the metal material, and even deform or damage it.

Excessive temperature will also cause the oil to deteriorate and lose its lubricating effect. At the same time, if the temperature is too high, the density of the air entering the cylinder will decrease, resulting in a decrease in the power of the diesel engine.

Therefore, the entire system of the diesel engine must be cooled. The role of the diesel generator cooling system is to ensure that the moving parts of the diesel engine, a few fixed parts, and the engine oil work at a normal temperature (about 80°C).

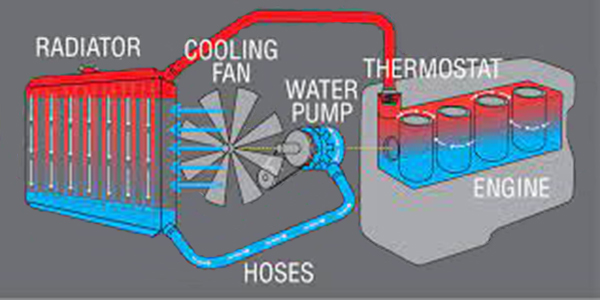

The diesel generator cooling system includes components such as a water tank, water pump, radiator, fan, temperature sensor, water pipe, and hydraulic control valve.

How Diesel Generator Cooling System Works

When the diesel engine starts, the water pump starts to work, pumping cooling water out of the water tank and flowing into the radiator through the water pipe. In the radiator, the cooling water exchanges heat with the air entering the radiator, dissipating the heat generated by combustion into the air. Then, the cooling water flows back to the water tank through the water pipe to complete a cycle.

In the cooling system, a temperature sensor can detect the temperature of the engine. When the temperature is too high, the hydraulic control valve will open to allow more cooling water to flow into the radiator to reduce the temperature of the engine. In addition, the fan can accelerate the airflow and improve the cooling effect.

The working principle of the entire cooling system is to exchange heat through circulating cooling water and air, dissipate the high temperature generated by combustion into the air, control the temperature of the engine, ensure the normal operation of the engine, and prolong the life of the engine.

The deterioration of the technical state of the diesel generator cooling system will directly affect the normal operation of the diesel engine. The deterioration of the technical state is mainly manifested in the fact that the scale of the cooling system reduces the volume and increases the water circulation resistance. At the same time, the thermal conductivity of the scale becomes poor, so that the heat dissipation effect decreases, and the temperature of the machine is high, which accelerates the formation of the scale. In addition, it is easy to cause the oil to oxidize, causing carbon deposits on piston rings, cylinder walls, valves, and other parts, causing increased wear and tear. Therefore, we need to pay attention to the diesel generator cooling system.

Diesel Generator Cooling System Operating Instructions

(1) Try to use soft water such as snow water and rainwater as cooling water.

(2) Maintain an appropriate water level, that is, the upper water chamber must not be lower than 8mm below the upper mouth of the water inlet pipe, and it should be replenished in time if it is too low.

(3) Master the correct method of adding water and releasing water. When the diesel engine is overheated and lacks water, it is not allowed to add cold water immediately, the load should be removed, and after the water temperature drops, add it slowly in a trickle under the running state.

(4) Keep the normal temperature of the diesel engine. After the diesel engine is started, it cannot start working until it is warmed up to above 60°C (the tractor can only start empty running when the water temperature is at least above 40°C). After working normally, the water temperature should be kept in the range of 80-90°C, and the maximum should not exceed 98°C.

(5) Check the belt tension. Press the middle part of the belt with a force of 29.4-49N, and the belt sag is 10-12mm. If it is too tight or too loose, loosen the fastening bolts of the generator bracket and adjust by moving the position of the generator pulley.

(6) Check the water leakage of the water pump, and observe the water leakage of the drain hole under the water pump cover, the water leakage should not exceed 6 drops within 3 minutes of parking, and replace the water seal if it is too much.

(7) The shaft bearing of the water pump should be lubricated with oil regularly. When the diesel engine works for 50 hours, butter should be added to the shaft bearing of the water pump.

(8) After the engine has been working for about 1000 hours, the scale in the cooling system should be cleaned.

Diesel Generator Liquid-Cooled System Operation Tips

River water, spring water, and well water are all hard water, containing a variety of minerals, which will precipitate out when the water temperature rises, and easily form scale in the cooling system, so they cannot be used directly. If you really want to use this kind of water, you should boil the water, settle it, and use the surface water. When the water shortage is replenished, clean soft water without impurities should be used.

If the water is cut off when the diesel engine is working, do not add water immediately, so as not to cause stress and cracks in the parts due to uneven cold and heat, or accidents caused by seizure. Water should be added only after the diesel engine is stopped and the standby temperature drops to the natural temperature.

In cold weather, water should not be released when the water temperature is high, in case the body is damaged due to a large temperature difference, the water must be released after the water temperature drops to 40°C, and the water tank cover should be opened, and the crankshaft should be turned to completely drain the water in the water pump and other places, so as not to freeze the radiator, cylinder head, cylinder block, and other parts.